Control valve for all types of purifiers with a single tank chamber.

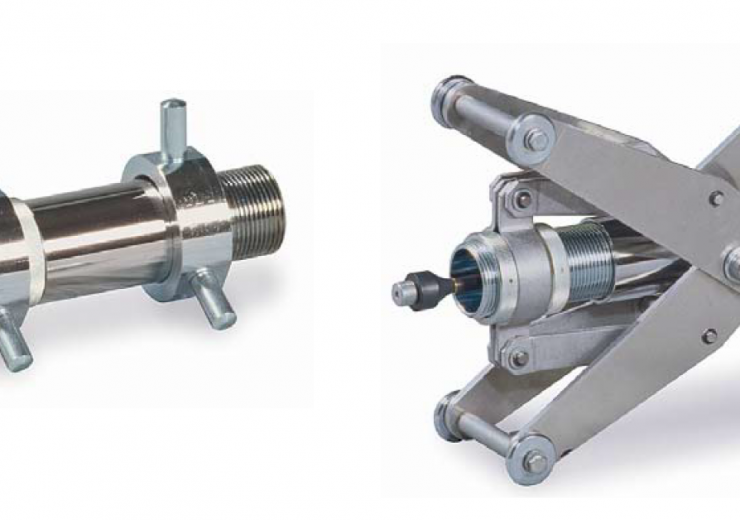

Clemco valve cooperating with pneumatic levers.

This device is a development of Hollo-Blast Junior capabilities.

The device is connected by hose to the cleaner in place of the standard nozzle. The abrasive is ejected through the scattering tip, which causes the stream to be directed to the internal surfaces of the cleaned pipe. The device is equipped with four double rings of different diameters, which when mounted on the body of the device determine the position in the axis of the pipe. The tip and sleeves are made of tungsten carbide.

This device is also connected in place of the standard nozzle. It is equipped with a centering trolley with three sets of guides of different lengths. The abrasive is ejected through two nozzles screwed into the rotary head. The built-in brake allows you to reduce the rotational speed of the head, maintaining the optimal sanding speed.

Two-position filter, with a carbon insert, with a higher degree of air purification. It is a portable device built into the frame allowing for easy and simple operation, transport, positioning and connection.

The filter is designed for cleaning oil, moisture and other impurities of compressed air for breathing from vapors.

Dustproof suit reinforced with leather recommended for harsh working conditions.

The suit protects against the effects of non-toxic mineral dusts with an area of 60 ŋm and partly against impact of reflected abrasive grains.

Dustproof suit reinforced with strong material – kodura.

High quality cowhide gloves.

The most popular helmet for operators in the blasting process. Its biggest advantages are high quality workmanship and easily replaceable parts. There are different variants of the product. Some helmets have additional rubber (designed for aggressive abrasives) or hearing protection. Res-3 should be completed with a system regulating the amount of breathing air entering. We have all spare parts for helmets.

A popular Clemco valve recommended when using less aggressive, non-metallic abrasives, e.g. sand.

The Schmidt Micro® valve gives you precise control over the amount of abrasive consumed. Suitable for all types of abrasives, ranging from lightweight plastic abrasives to heavy ones such as round or sharp-edged steel shots.

The successor of the Schmidt Micro valve, includes a built-in knob position indicator (VPI – Virtual Position Indicator) and an inspection hole.