Cabin cleaning / sandblasting machines

Specification

| Size: | According to investor’s requirements |

| Abrasive material: | Depending on the choice of valves, our cleaners can work with all abrasives |

| Abrasive valves: | Micro Schmidt, FSV Clemco, Thompson Schmidt, Thompson II Schmidt, Thompson XL Schmidt, more |

| Control valves: | Combo Schmidt, more |

Guarantee of quality

Our cleaners are made of the highest quality components. We only use original valves from reputable companies such as Schmidt and Clemco.

WARNING! We recommend avoiding cheap valves from unknown manufacturers whose quality leaves much to be desired.

Why is it worth investing in our cleaners??

- The construction is based on the highest quality components.

- Adapting the device to customer needs. We adjust the size, abrasive valves, controls and many other parts to the investor’s preferences and requirements.

- The technology used allows for convenient and quick service.

- Ideal for cleaning smaller items.

DESCRIPTION

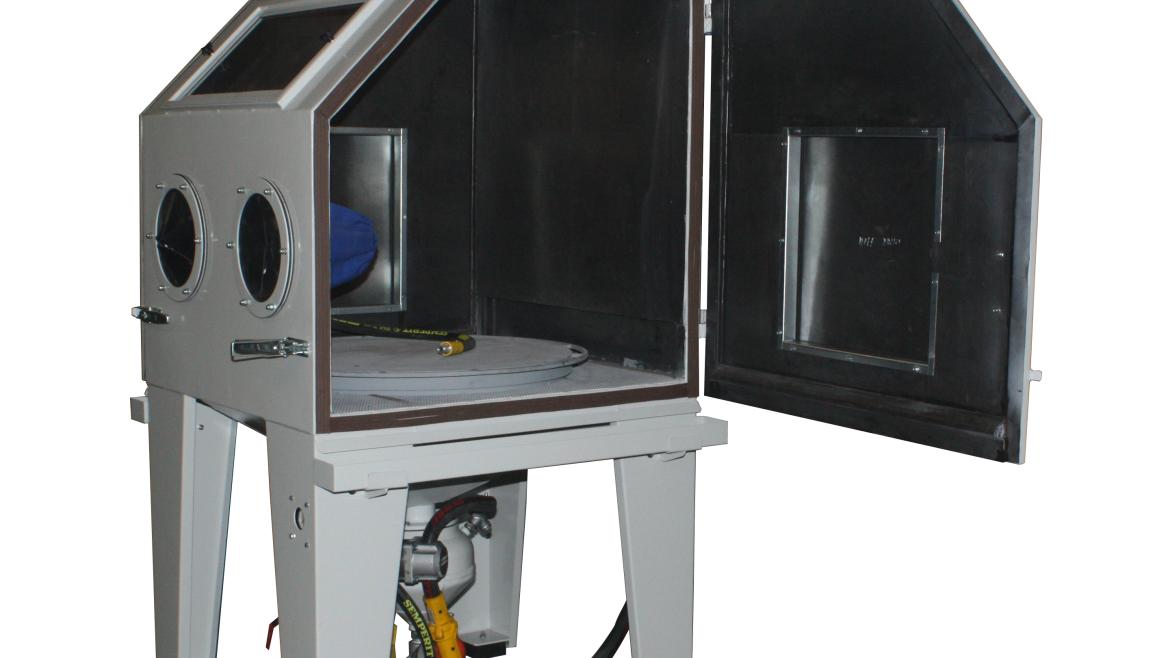

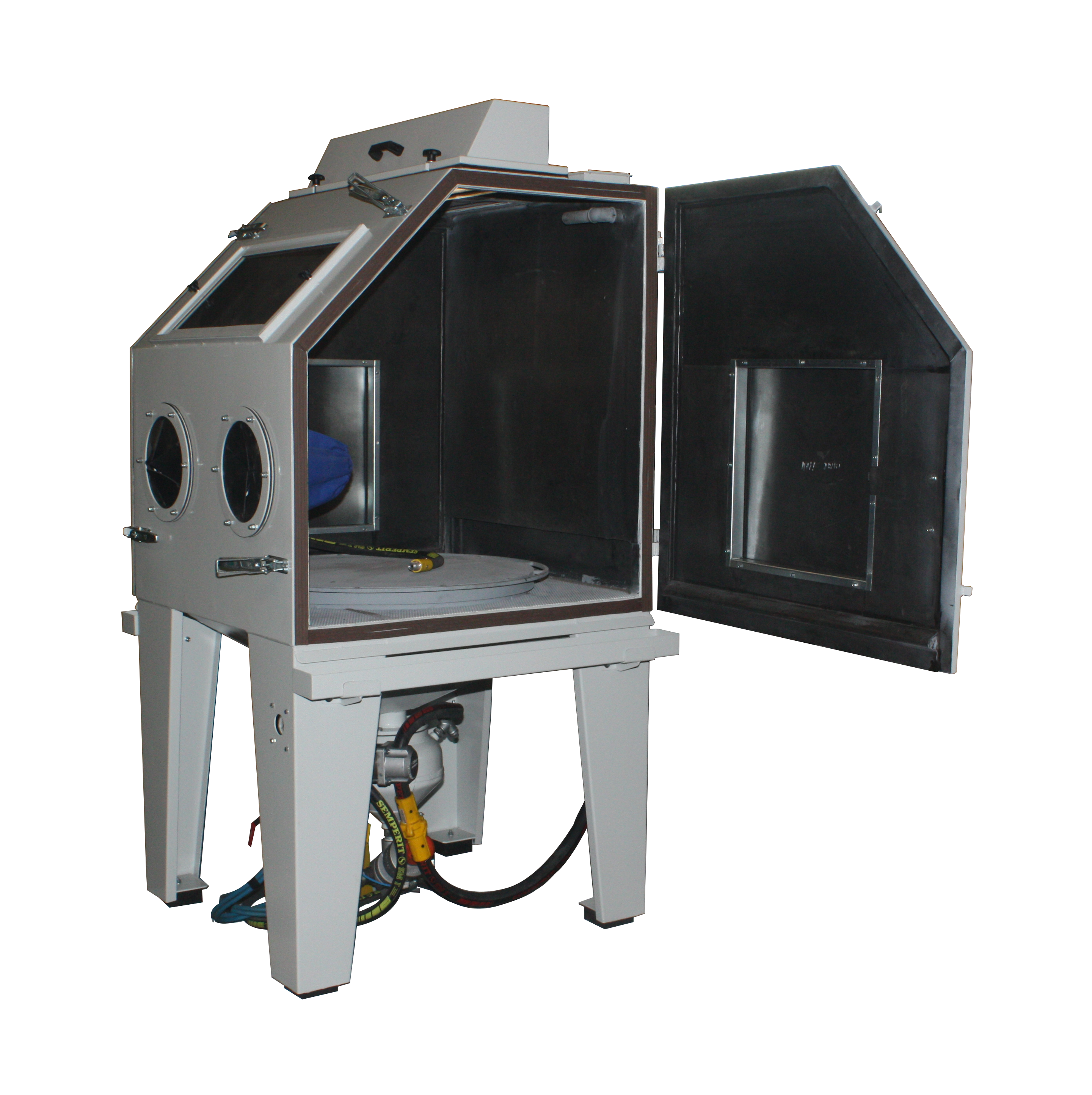

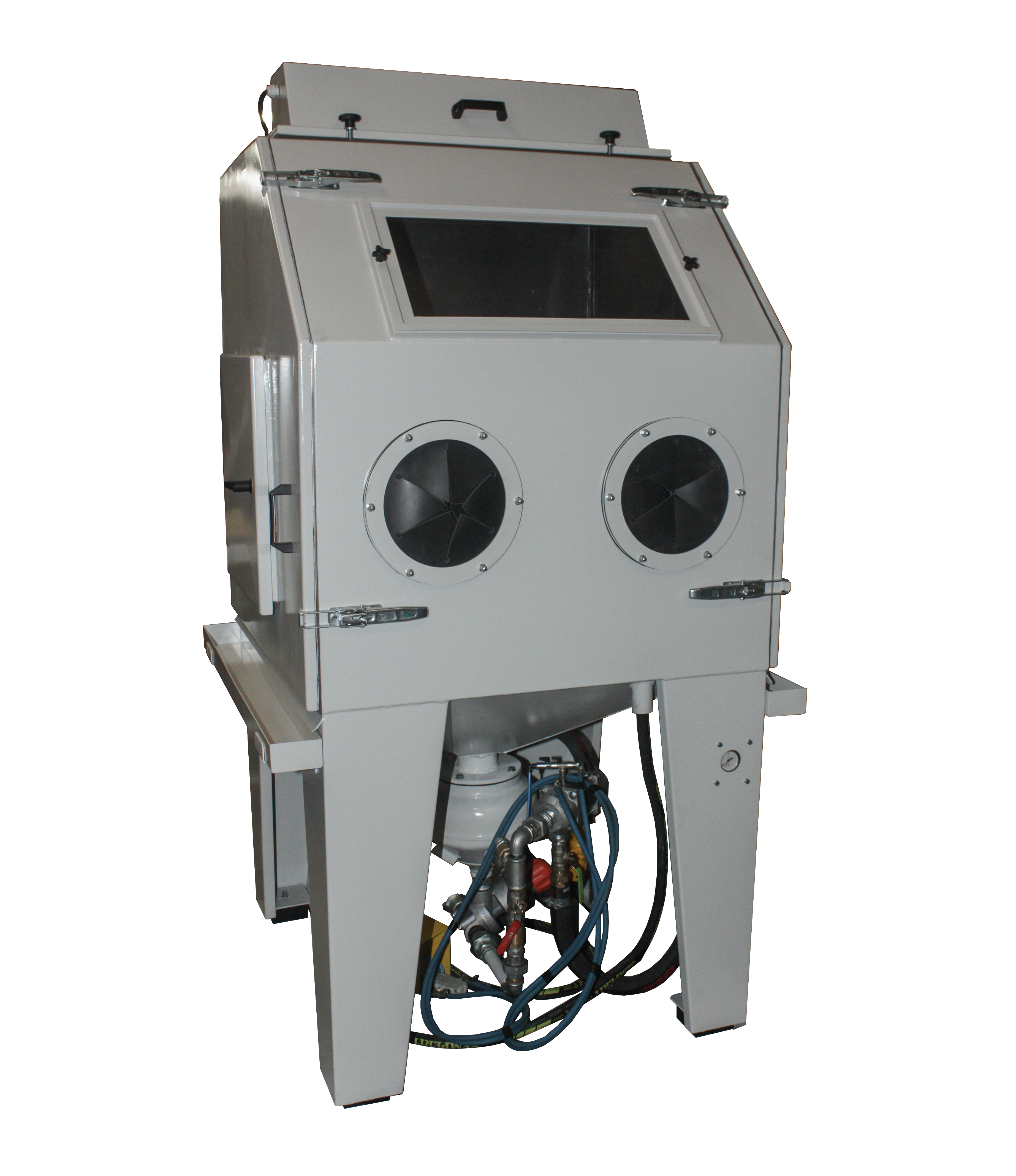

Szatkowski cabin cleaners are used for abrasive blasting of elements inside the cabin. The operator performs work in special protective gloves, using the sanding nozzle inside the device.

The cabin sizes are tailored to customer requirements, always taking into account the elements that will be cleaned in a given device.

We design our blast cabinets using original Schmidt® valves from the USA, which make work with any type of abrasive comfortable and efficient.

Our cabin cleaner can be loaded from the side or from above, have a rotary table for convenience of work, work in a closed circuit of abrasive circulation and even have a cabin dust removal system for maximum transparency during work.

We offer pneumatic and injector solutions, depending on individual expectations.