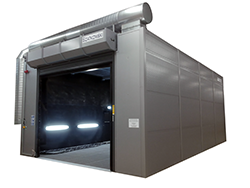

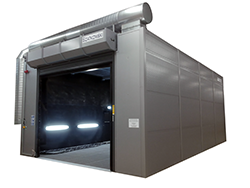

Produkujemy, dostarczamy i kompleksowo montujemy komory śrutownicze do czyszczenia strumieniowo-ściernego (tzw. piaskowania, śrutowania).

Dostarczamy profesjonalne akcesoria i osprzęt roboczy do prac czyszczenia strumieniowo-ściernego.

Unikatowe urządzenie służące do wykonywania powłok antykorozyjnych oraz osprzęt.

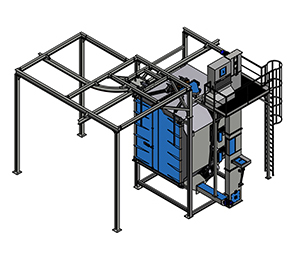

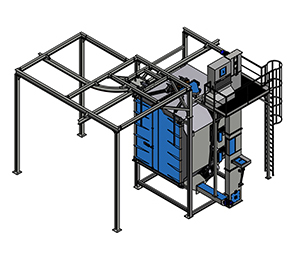

Nowoczesne oczyszczarki wirnikowe dopasowane do potrzeb klienta.

Produkujemy oczyszczarki pneumatyczne (piaskarki). Mało i wielkogabarytowe, stacjonarne oraz mobilne.

Proponujemy Państwu kompresory renomowanych firm, które sprawdzą się w każdych warunkach.

W naszej ofercie znajdziecie Państwo agregaty i akcesoria malarskie oraz urządzenia pomiarowe.

Wiele rodzajów ścierniw w różnych granulacjach.

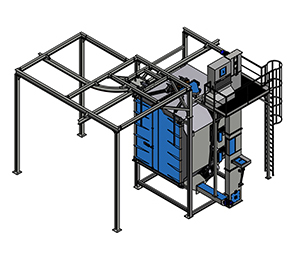

Automatyczne urządzenia do obróbki strumieniowo-ściernej oraz robotyzacja procesów pracy w komorze śrutowniczej.

Produkujemy, dostarczamy i kompleksowo montujemy komory śrutownicze do czyszczenia strumieniowo-ściernego (tzw. piaskowania, śrutowania).

Dostarczamy profesjonalne akcesoria i osprzęt roboczy do prac czyszczenia strumieniowo-ściernego.

Unikatowe urządzenie służące do wykonywania powłok antykorozyjnych oraz osprzęt.

Nowoczesne oczyszczarki wirnikowe dopasowane do potrzeb klienta.

Automatyczne urządzenia do obróbki strumieniowo-ściernej oraz robotyzacja procesów pracy w komorze śrutowniczej.

Proponujemy Państwu kompresory renomowanych firm, które sprawdzą się w każdych warunkach.

W naszej ofercie znajdziecie Państwo agregaty i akcesoria malarskie oraz urządzenia pomiarowe.

Wiele rodzajów ścierniw w różnych granulacjach.

Produkujemy oczyszczarki pneumatyczne (piaskarki). Mało i wielkogabarytowe, stacjonarne oraz mobilne.

Produkujemy, dostarczamy i kompleksowo montujemy komory śrutownicze do czyszczenia strumieniowo-ściernego (tzw. piaskowania, śrutowania).

Dostarczamy profesjonalne akcesoria i osprzęt roboczy do prac czyszczenia strumieniowo-ściernego.

Unikatowe urządzenie służące do wykonywania powłok antykorozyjnych oraz osprzęt.

Nowoczesne oczyszczarki wirnikowe dopasowane do potrzeb klienta.

Automatyczne urządzenia do obróbki strumieniowo-ściernej oraz robotyzacja procesów pracy w komorze śrutowniczej.

Proponujemy Państwu kompresory renomowanych firm, które sprawdzą się w każdych warunkach.

W naszej ofercie znajdziecie Państwo agregaty i akcesoria malarskie oraz urządzenia pomiarowe.

Wiele rodzajów ścierniw w różnych granulacjach.

Produkujemy oczyszczarki pneumatyczne (piaskarki). Mało i wielkogabarytowe, stacjonarne oraz mobilne.

Czym się zajmujemy

Nasze Usługi

Lista firm, których urządzenia i maszyny regularnie serwisujemy jest bardzo długa. Obsługujemy produkty własne, jak i innych dostawców.

Nasza firma oferuje wykonanie usługi na miejscu i u Klienta. Technologie nakładania farb jakie wykorzystujemy to: malowanie hydrodynamiczne, pneumatyczne, plus wykończenie precyzyjne powierzchni trudnodostępnych metodami ręcznymi.

Firma STG specjalizuje się w wykonywaniu metalizacji natryskowej, m.in. konstrukcji stalowych, aluminium. Możemy pochwalić się wieloletnim doświadczeniem oraz znaczną liczbą zadowolonych klientów.

Wszystkim zainteresowanym stałym podnoszeniem kwalifikacji operatorów maszyn i urządzeń związanych z antykorozją, proponujemy kompleksowe szkolenia, prowadzone przez naszych najbardziej doświadczonych pracowników. Każdy uczestnik może otrzymać pisemne potwierdzenie odbycia przeszkolenia przez naszą kadrę.

Obróbka strumieniowo-ścierna, polegająca na wykorzystaniu sprężonego powietrza do narzucenia materiału ściernego (ścierniwa) na czyszczone podłoże.

Czym się zajmujemy

Nasze Usługi

Lista firm, których urządzenia i maszyny regularnie serwisujemy jest bardzo długa. Obsługujemy produkty własne, jak i innych dostawców.

Nasza firma oferuje wykonanie usługi na miejscu i u Klienta. Technologie nakładania farb jakie wykorzystujemy to: malowanie hydrodynamiczne, pneumatyczne, plus wykończenie precyzyjne powierzchni trudnodostępnych metodami ręcznymi.

Firma STG specjalizuje się w wykonywaniu metalizacji natryskowej, m.in. konstrukcji stalowych, aluminium. Możemy pochwalić się wieloletnim doświadczeniem oraz znaczną liczbą zadowolonych klientów.

Wszystkim zainteresowanym stałym podnoszeniem kwalifikacji operatorów maszyn i urządzeń związanych z antykorozją, proponujemy kompleksowe szkolenia, prowadzone przez naszych najbardziej doświadczonych pracowników. Każdy uczestnik może otrzymać pisemne potwierdzenie odbycia przeszkolenia przez naszą kadrę.

Obróbka strumieniowo-ścierna, polegająca na wykorzystaniu sprężonego powietrza do narzucenia materiału ściernego (ścierniwa) na czyszczone podłoże.

Czym się zajmujemy

Nasze Usługi

Lista firm, których urządzenia i maszyny regularnie serwisujemy jest bardzo długa. Obsługujemy produkty własne, jak i innych dostawców.

Nasza firma oferuje wykonanie usługi na miejscu i u Klienta. Technologie nakładania farb jakie wykorzystujemy to: malowanie hydrodynamiczne, pneumatyczne, plus wykończenie precyzyjne powierzchni trudnodostępnych metodami ręcznymi.

Firma STG specjalizuje się w wykonywaniu metalizacji natryskowej, m.in. konstrukcji stalowych, aluminium. Możemy pochwalić się wieloletnim doświadczeniem oraz znaczną liczbą zadowolonych klientów.

Wszystkim zainteresowanym stałym podnoszeniem kwalifikacji operatorów maszyn i urządzeń związanych z antykorozją, proponujemy kompleksowe szkolenia, prowadzone przez naszych najbardziej doświadczonych pracowników. Każdy uczestnik może otrzymać pisemne potwierdzenie odbycia przeszkolenia przez naszą kadrę.

Obróbka strumieniowo-ścierna, polegająca na wykorzystaniu sprężonego powietrza do narzucenia materiału ściernego (ścierniwa) na czyszczone podłoże.

Historia

Powstanie firmy Szatkowski

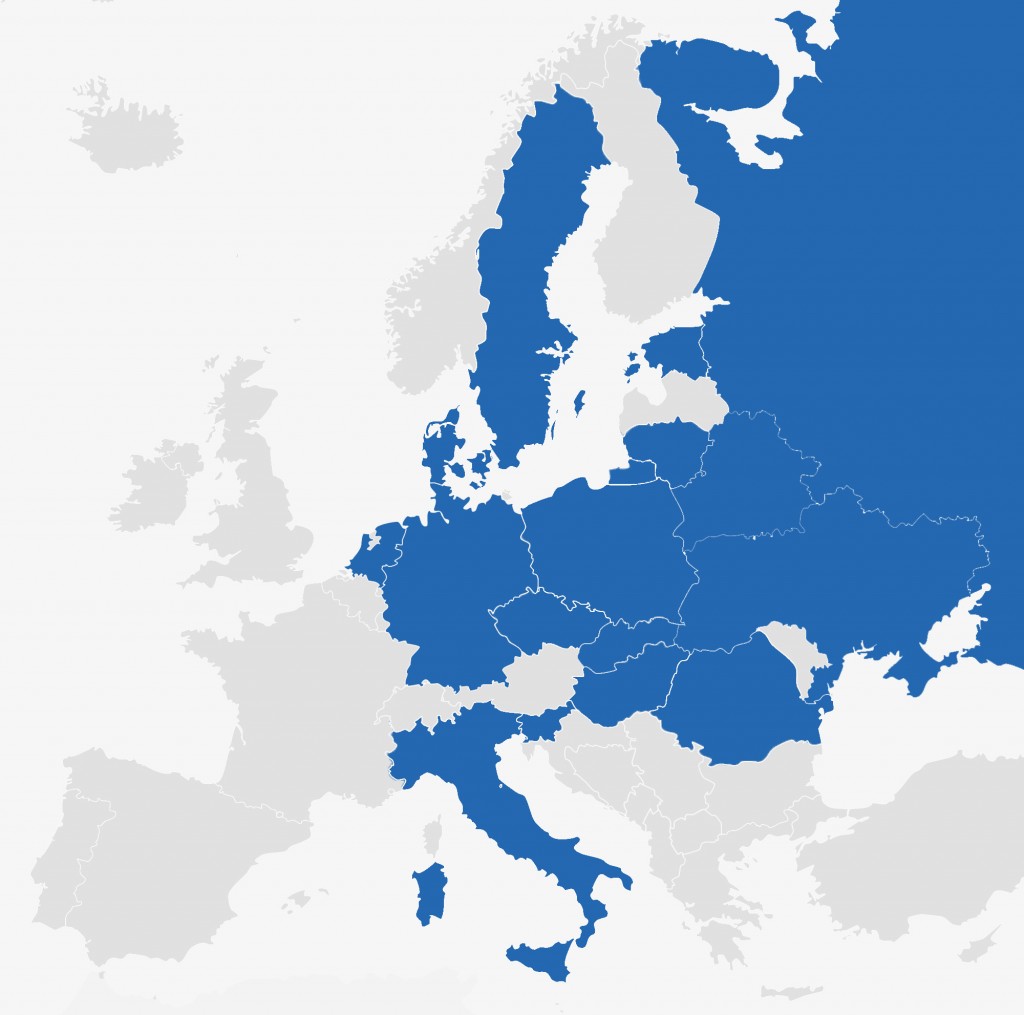

Szatkowski Technological Group (STG) działa w branży urządzeń i usług antykorozyjnych od 1995 roku.

W tym okresie wyprodukowaliśmy i dostarczyliśmy naszym klientom w kraju i za granicą szereg komór śrutowniczych oraz urządzeń do czyszczenia strumieniowo-ściernego.

Świadczyliśmy również kompleksowe usługi zabezpieczeń antykorozyjnych w naszym zakładzie, u klienta, lub ustalonym miejscu w kraju i za granicą.

Historia

Początki

Wraz z partnerami tworzymy pierwszą komorę śrutowniczą.

Historia

Dynamiczny rozwój

Realizujemy pierwsze duże projekty sygnowane naszą marką. Również w tym roku powstaje pierwsza nasza komora śrutownicza poza Polską (na Litwie).

Historia

Nowoczesne rozwiązania

Początek pracy nad automatyzacją procesu czyszczenia oraz wprowadzaniem do naszych produktów elementów Przemysłu 4.0.

Historia

25 lat istnienia

Obchodzimy jubileusz 25-lecia istnienia jako jeden z największych producentów komór śrutowniczych i urządzeń do prac antykorozyjnych.

nasze zasięgi

Szatkowski Technological Group w liczbach